Peter

From your descrription and the photo of the underside of the phosphur bronze platter, an easy workaround may be to just remove the Allen bolts and locate one of the empty holes over the raised pin on the bearing housing lip to achieve a flush fit.

By carefully listening (once everything is up and running) you could rotate the platter to align each of the bolt holes in turn to see whether there was any sonic difference and if so which was the preferred position and then mark it for future reference.

The bolts could then be replaced and aligned and listening tests would again indicate which was the preferred option - bolts or no bolts.

That way, you would not have irrevocably altered the design of your deck by filing down/removing the pin.

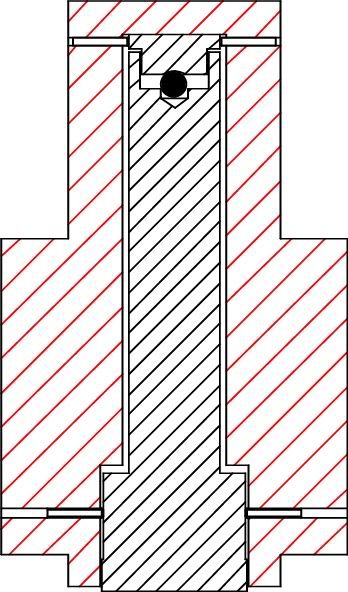

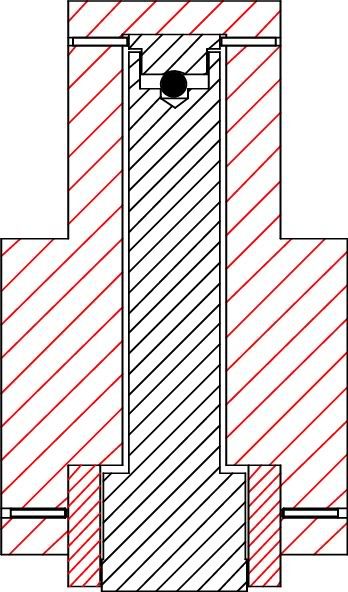

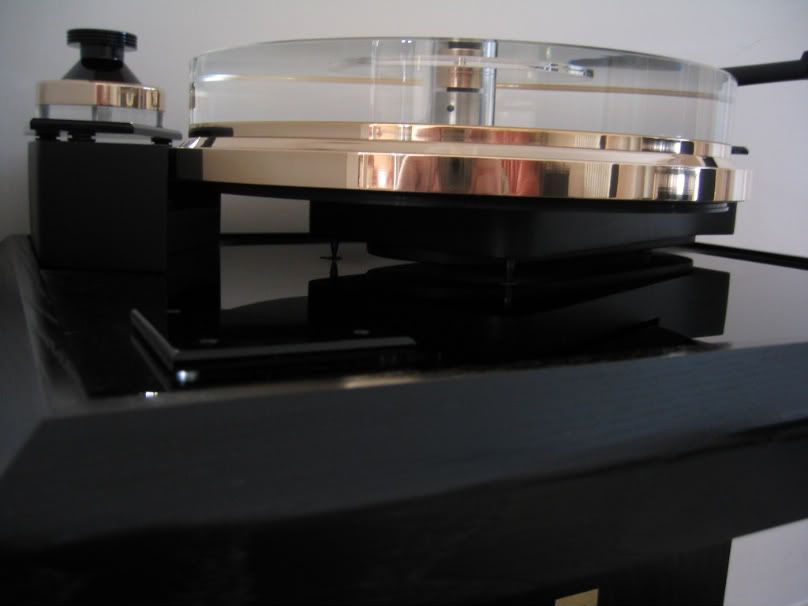

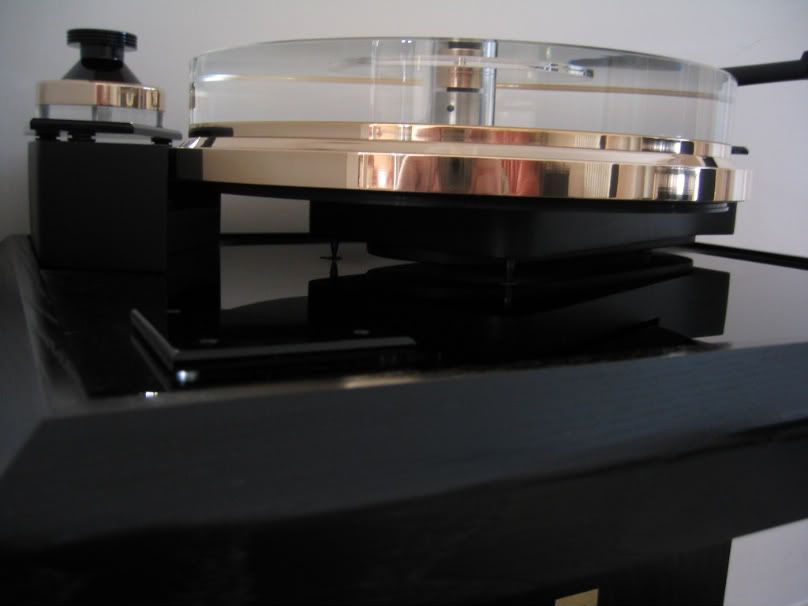

Unfortunately I didn't take any photos of the disassembled bearing when the Oxford was in my posession. The only other pics I have are these which show the bearing housing and sorbothane spacer underneath the detachable spindle visible through the clear acrylic upper platter. The ubiquitous black ash finish of the 80's does look rather dated now!

With SMEV and Koetsu Rosewood Signature mc cartridge.

Another nice aesthetic touch was the veneered 'skirt' which could be raised up the stand and rested on the rear lip below the DIN socketry to allow the four lock nut spikes to be levelled at the base of the stand. The skirt could then be slid back down to hide the spikes.

Another view of the component parts showing the exemplary engineering and finish.

Steve.

My System:- dCS Vivaldi Transport + dCS Vivaldi Apex DAC + dCS Vivaldi Master Word Clock + dCS Vivaldi Upsampler Plus, Aurender N20 Music Server/Streamer, TW Raven One tt/Graham Phantom II/Transfiguration Orpheus L & Audio Technica ART20 mc's, Whest Titan Pro, D'Agostino Momentum HD pre/S250 MxV power amp, TAD CR-1 MKII loudspeakers, REL Gibraltar G2 subs, Coherent Systems BD Mains, interconnects & speaker cables, Sablon Audo EVO USB cable, Tellurium Q Ultra Silver power cords, Ziro Disclosure & Vertex Roraima Hi-Rez power cords + Furutech FI connectors, Stillpoints ESS racks/component stands, Vertex Aletheia PSU2 balanced power supply, Coherent Systems RTZ3 ground box + CR/BD cables, Acoustica Applicata DaaD room treatment, Mutec Ref10 SE-120.

Reply With Quote

Reply With Quote

Originally Posted by YNWaN

Originally Posted by YNWaN

.

.