Found some more pics from my archives.

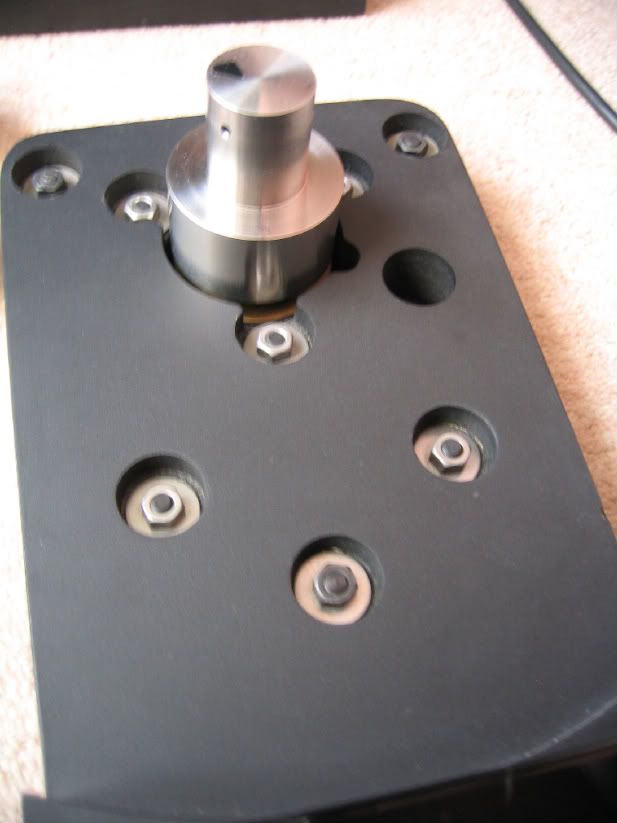

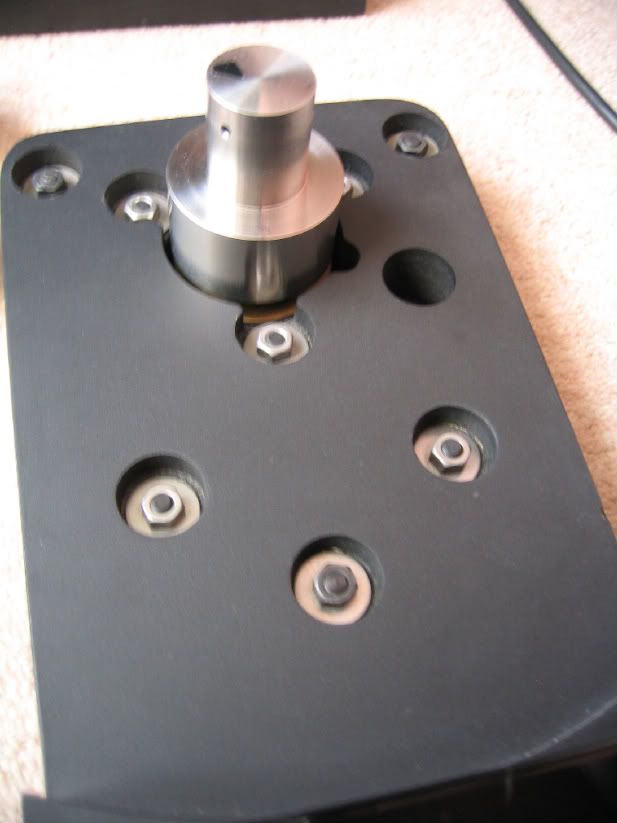

This shows the top of the 45kg sand-filled plinth/stand which sits on 4 x adjustable spikes for levelling. The void beneath the top plate houses the turntable power supply which is connected to the motor/speed switch via a DIn socket on the rear.

Next up, the top steel plate in position with the three sorbothane suspension housings which have inset threads and bolts to engage and support the three downward pointing spikes on the sub-chassis.

The top plinth with motor housing and speed switch is then bolted to the steel plate. Three holes allow the spikes on the sub-chassis to engage with the adjustable bolts on the suspension housings.

Views of the MDF/steel sub-chassis showing the inverted bearing housing and the underneath with the protruding spikes.

The component parts.

The assembled product playing a record (the 15kg phosphur bronze two-piece platter and weight buffs up nicely with some Solvol Autosol).

Steve.

My System:- dCS Vivaldi Transport + dCS Vivaldi Apex DAC + dCS Vivaldi Master Word Clock + dCS Vivaldi Upsampler Plus, Aurender N20 Music Server/Streamer, TW Raven One tt/Graham Phantom II/Transfiguration Orpheus L & Audio Technica ART20 mc's, Whest Titan Pro, D'Agostino Momentum HD pre/S250 MxV power amp, TAD CR-1 MKII loudspeakers, REL Gibraltar G2 subs, Coherent Systems BD Mains, interconnects & speaker cables, Sablon Audo EVO USB cable, Tellurium Q Ultra Silver power cords, Ziro Disclosure & Vertex Roraima Hi-Rez power cords + Furutech FI connectors, Stillpoints ESS racks/component stands, Vertex Aletheia PSU2 balanced power supply, Coherent Systems RTZ3 ground box + CR/BD cables, Acoustica Applicata DaaD room treatment, Mutec Ref10 SE-120.

Reply With Quote

Reply With Quote

Originally Posted by peter

Originally Posted by peter